In Augmented Reality, Virtual Reality News and Mixed Reality News

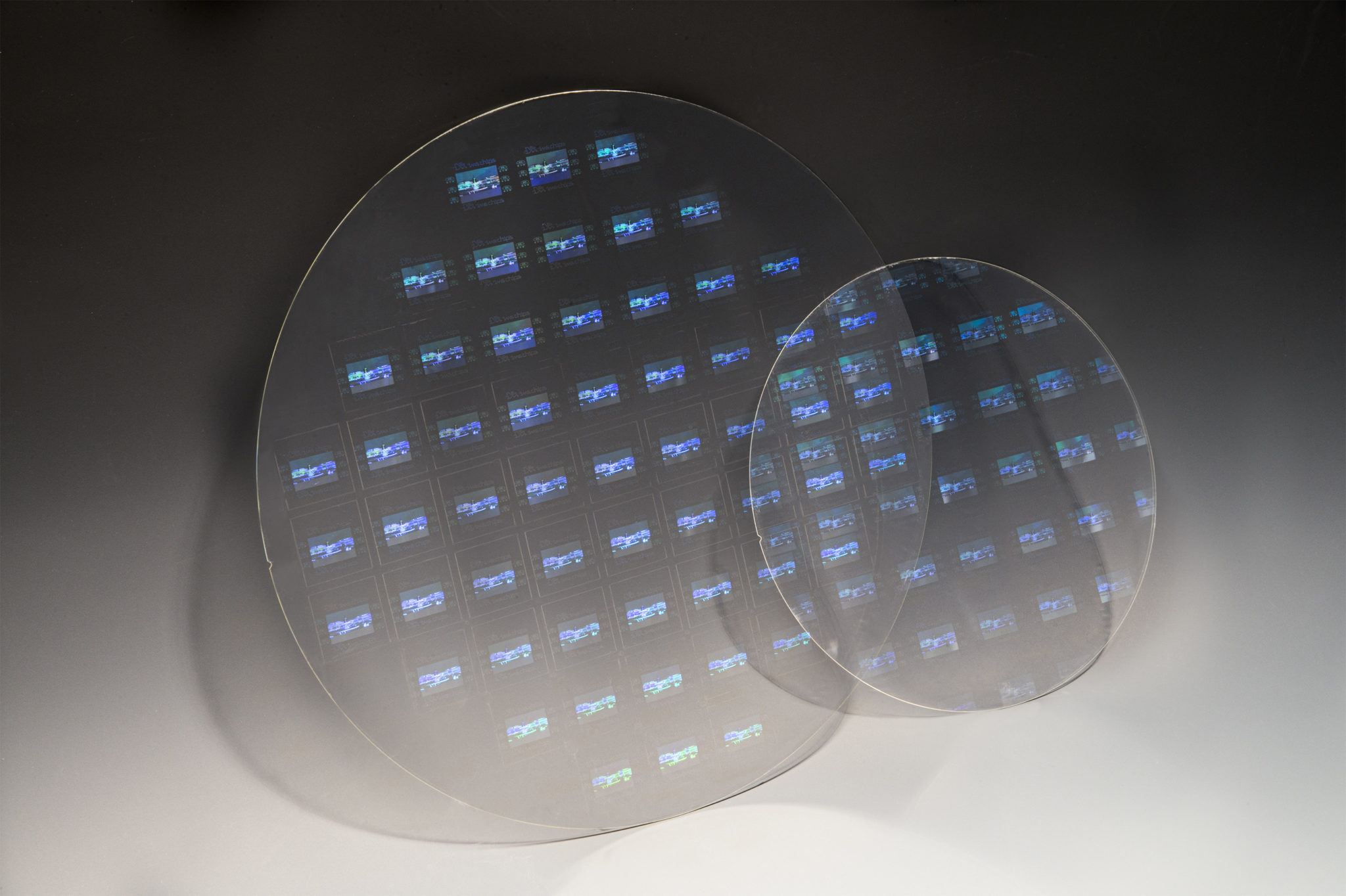

August 28, 2019 – EV Group, a supplier of wafer bonding and lithography equipment for the Microelectromechanical systems (MEMS), nanotechnology and semiconductor markets, has today announced that it has partnered with SCHOTT, a manufacturer of specialty glass and glass ceramics, to demonstrate the readiness of 300-mm (12 inch) nanoimprint lithography (NIL) for high-volume patterning of high-refractive index (HRI) glass wafers used in the manufacture of waveguides/light guides for next-generation augmented and mixed reality (AR/MR) headsets.

The partnership involves EVG’s proprietary SmartNIL process and SCHOTT RealView high-refractive index glass wafers, and will be carried out within EVG’s NILPhotonics Competence Center at the company’s headquarters in Austria.

“Scaling up to 300-mm manufacturing of high-refractive index glass wafers is critical to achieving the production volumes at the economies of scale that our customers need to meet growing market demand for today’s and tomorrow’s leading AR/MR devices,” stated Dr. Ruediger Sprengard, Head of Augmented Reality at SCHOTT. “Through this joint effort, EVG and SCHOTT are demonstrating the equipment and supply-chain readiness for 300-mm HRI glass manufacturing today.”

According to EV Group, the use of NIL to pattern glass substrates with structures for photonics applications has been limited to 200-mm substrates. The company stated that this migration to 300-mm wafer processing is an important step forward in bringing AR and MR headsets into the mass consumer and industrial markets. However, maintaining high substrate quality and process uniformity on these larger substrates is difficult to control, and requires advanced automation and process control capabilities.

EVG’s SmartNIL technology is aimed at addressing the needs of nanopatterning, and this past June, EVG introduced the HERCULES NIL 300 mm, which brings SmartNIL into 300-mm manufacturing to support the production needs for a variety of devices and applications, including optical devices for AR, MR and virtual reality (VR) headsets, as well as 3D sensors, bio-medical devices, nanophotonics and plasmonics.

Markus Wimplinger, Corporate Technology Development and IP Director at EV Group, commented: “We are excited to partner with companies like SCHOTT to demonstrate the value of EVG’s NIL solutions in not only enabling the development of new technologies and processes, but also accelerating their introduction to mass markets. This current work we are doing with SCHOTT proves the maturity of NIL equipment and processes, and is laying the groundwork for 300-mm manufacturing for a variety of exciting new photonics-based products and applications.”

SCHOTT RealView high-refractive index glass wafers are used in AR/MR devices and are available in mass production. The product portfolio offers refractive indices up to 1.9, enabling deeply immersive AR/MR applications with a wider field of view of up to 65 degrees, according to SCHOTT. The company unveiled the first generation of its RealView glass wafers in 2018.

SCHOTT will be showcasing a 300-mm SCHOTT RealView glass wafer patterned with EVG’s SmartNIL technology at the China International Optoelectronic Expo (CIOE), to be held September 4-7 at the Shenzhen Convention Center.

Image credit: EV Group

About the author

Sam is the Founder and Managing Editor of Auganix. With a background in research and report writing, he has been covering XR industry news for the past seven years.