In Augmented Reality and Mixed Reality News

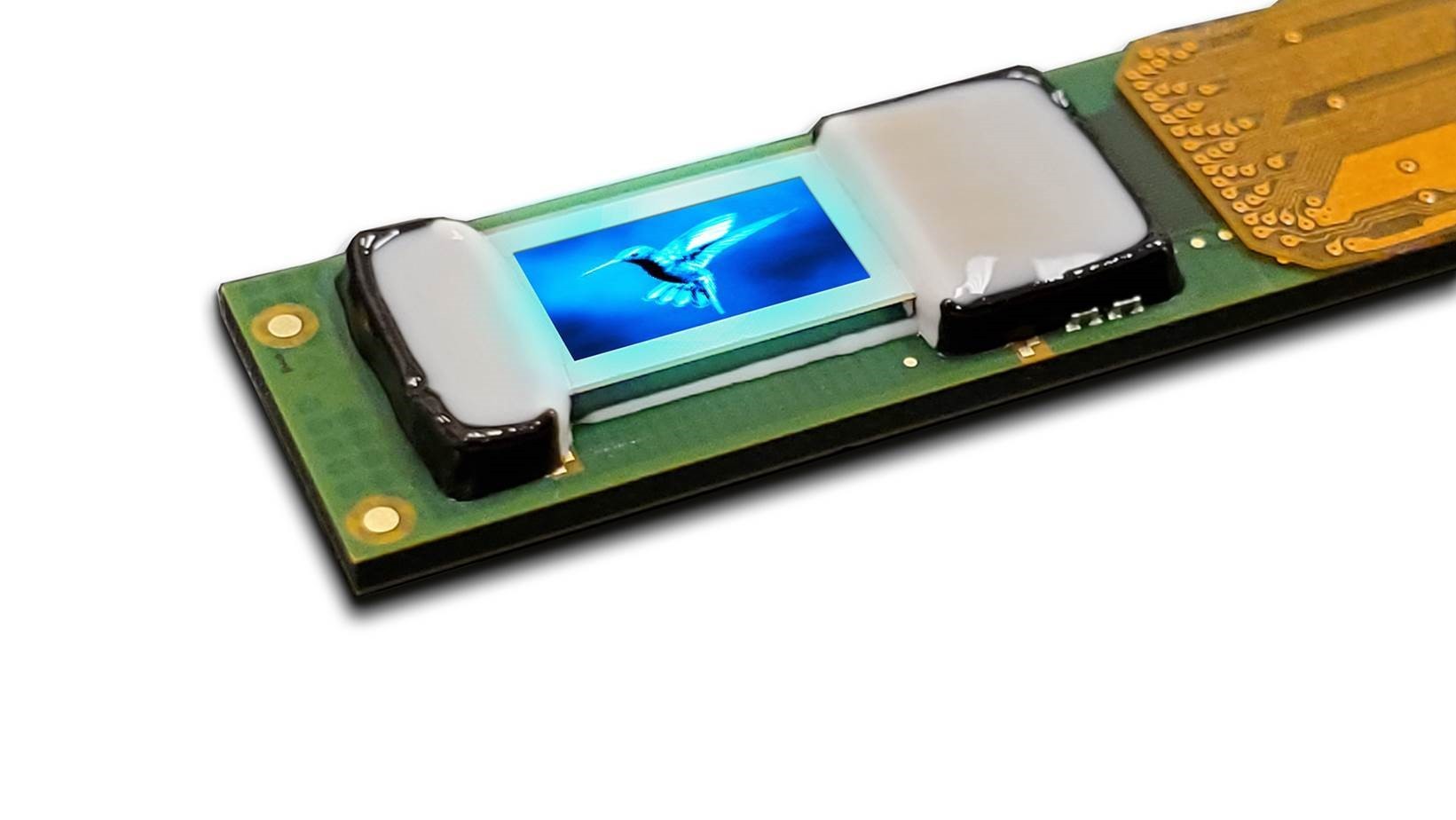

May 5, 2020 – Compound Photonics, a provider of compact high-resolution microdisplay solutions for augmented and mixed reality (AR/MR), has today announced the availability of its high-performance digital backplane to microLED developers worldwide for integration into complete microdisplay subsystems.

The company states that its microdisplay solutions are optimized to serve the augmented reality and mixed reality markets, where high performance, small form factor, and low power consumption are most critical.

As a result, Compound Photonics re-engineered its market-ready LCoS backplane technology into a constant current drive configuration for microLED pixels based on its 0.26” diagonal (~3 μm pixel) 1080p display format. According to Compound Photonics, its backplane is driven by the company’s NOVA display drive architecture, which enables complete display subsystems to meet the above mentioned critical AR requirements for compactness, optical performance and brightness with high frame rate, low latency and low power consumption.

“Our custom, constant current pixel circuit design provides greater tolerance to forward voltage variation and IR drops in the microLED array resulting in a previously unattainable level of uniformity. It additionally features globally on-the-fly programmable pixel current control that greatly increases the system bandwidth, enabling higher frame rates while maintaining full bit depth,” commented Ian Kyles, Compound Photonics’ Vice President of Electrical/Software Engineering. “The backplane also has additional steering pixels beyond its native 2048 x 1080 resolution to enhance alignment/integration of the display within the optical system.”

The company states that microLED developers using its backplane can access the company’s monolithic integrated display module (IDM) (7.25 x 15.5 x 3.1 mm) with a low pin count interconnect and a direct MIPI input packaged into a compact subsystem amenable to smaller optical engine size. The IDM integrates Compound Photonics’ proprietary NOVA drive architecture’s software defined platform to enable customizable frame-by-frame control of video frame rates (up to 240 Hz), bit depth, and other parameters to optimize for low latency, short persistence and low power while maintaining near 100% duty cycle according to type of image content and use case.

Andrew Shih, Compound Photonics’ Marketing and Business Development Manager added, “Process integration compatibility is also important, as bonding of the microLED array to the backplane requires a highly planar interface. Compound Photonics’ backplane wafers feature excellent planarity, a direct benefit from extensive process tuning work to meet earlier LCoS requirements. By partnering with Compound Photonics, whose backplane technology facilitates both wafer level process integration and a direct path to a complete NOVA-based microdisplay subsystem solution, microLED developers can focus on their core competencies in compound semiconductor photonic device engineering and process development while reducing development time and cost.”

A provisional backplane reference specification is presently available for customer review from Compound Photonics, and the company states that it is currently accepting engagements with microLED developers.

Image credit: Compound Photonics

About the author

Sam is the Founder and Managing Editor of Auganix. With a background in research and report writing, he has been covering XR industry news for the past seven years.