This is a contributed piece.

Augmented reality (AR) is solving the industrial skills gap. That’s a fact. Industrial engineering is a rapidly ageing industry, with at least a quarter of all workers estimated to be over 50 years old and starting to think about the end of their careers. There’s not as much new blood coming in as there once was, though whilst interest seems to be waning, augmented reality is offering hopeful signs of a resurgence.

With AR existing in a familiar middle ground between technology, education, skills development, and industrial training, we’re going to explain how it found its place and why its functions can be leveraged.

Zero Risk Training

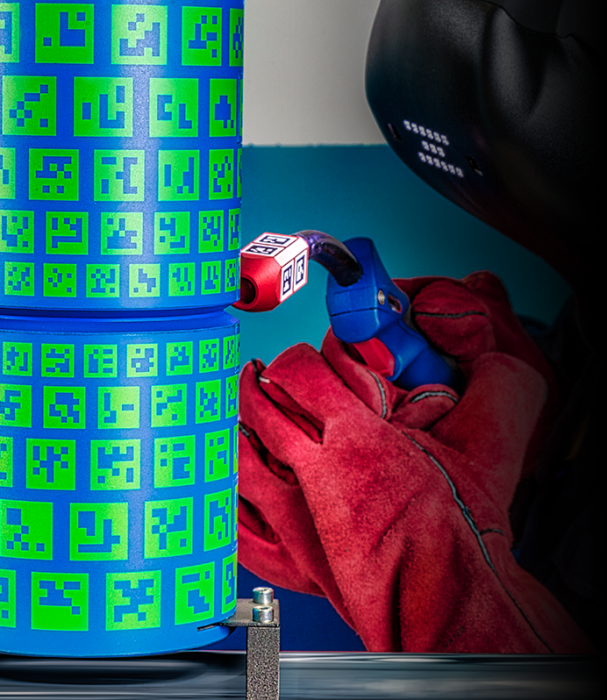

The creation and implementation of augmented reality in industrial skills training, such as welding, for example, has helped to drive improved safety levels. For decades, trainers have had to be overly cautious when training the unskilled in potentially dangerous environments. Companies such as Soldamatic have created AR welding software that is designed to help reduced the rate of accidents among clients, in some cases by up to 84%.

Safe and controlled AR programs allow trainees and new hires to practice routine, everyday tasks, without injury, endangerment, or equipment. This allows them to relax, tackle their fear, manage their anxiety, and better understand machinery functions without an element of danger. The other side of the coin, for educators, is that the quality of education is not reduced by using software rather than hardware. Skill development suddenly becomes more scalable without reducing risk.

As a result, beginners stand to benefit from safe AR industrial skills training that leverages both a user’s familiarity of technology with a no-risk training programme. A lack of experience no longer needs to equate to increased risk.

Reduced Costs

One of the biggest benefits to the industrial skills training industry is the cost reduction factor. Training can be scaled, delivered further afield, and reduce consumable wastage, all while significantly dropping costs.

Remote assistance has become a major part of AR’s function in industrial settings, both in application and training, since it allows for the provision of highly-skilled expertise for support and training. This benefits remote businesses and projects, as well as trainees in difficult-to-reach areas. For example, this means that a business in the UK with projects in other continents can send their trainees overseas or hire local workers near sites and train them through AR software. Human resources savings are made by removing the need for in-person expertise.

Of course, concessions must be made for the initial setup costs of AR software and training equipment, but it is long-lasting, reusable, and sustainable, with the ROI self-evident. One example is from Scope AR, a provider of an AR work instruction and remote assistance platform. Scope AR helped NASA to save USD $1 million on the very first day of using the company’s application. The AR overlay spotted that one mylar panel was laid backwards against a titanium part of the Orion space capsule. As a result, Scope AR’s software prevented an engineer from placing the module in the wrong location — an error that would have destroyed the million-dollar piece of sheet metal.

The cost savings in training can be even greater than this, especially when multiplying the number of learners around the world who can leverage the technology with the educators who can save on time, travel, consumables, and expertise costs. Most learners will even come prepared with their own smartphones or tablets, further reducing the initial setup costs as they can download apps and access learning materials on their own time.

Smaller firms that are trying to deliver cost savings through technology can realize instant savings on every lesson they hold through AR, avoiding the outlay of seminars, classes, and in-person educators. Improved information, engagement, and expertise, combined with reduced accidents and consumables mean there are only wins.

Remote Experts

Technology now allows experts around the globe to connect with their students. Spurred on by the changing landscape of the pandemic, Zoom meetings encouraged the world to think more digitally and leverage VoIP (Voice over Internet Protocol) for education.

Some AR tools now have built-in video chats that can connect multiple people and allow notes to be overlaid. Imagine the scenario: A machine breaks down and the people who know how to fix it are on the other side of the planet. With augmented reality, the engineer fixing the machine can make a call and remote experts can draw instructions on their screens remotely while guiding the engineer through the problem.

The same is true of skills training. An expert in Australia can teach an online class to students in London, Nairobi and Bangkok, without having to be physically located there. If the right AR tools are used, the students get a valuable, engaging, and memorable learning experience. The AR tools must lock in the information into the 3D environment so that the learners can enjoy a combination of visualisation along with the guidance of a remote expert. This will help their skill retention and push them from beginners to competent engineers.

Engagement & Retention

It’s important to be acutely aware of the ongoing skills gap in many major industries, including engineering and manufacturing. Many young people aren’t quite sure what to do for a career, due to the diversity of options presented to them. It wasn’t like this fifty years ago, where individuals would often take the best local career available, or follow the family business. Young people have too many options now, and fewer and fewer are considering physical jobs as opposed to the opportunity that digital jobs offer.

The interesting nature of augmented reality is likely to change the opinions of younger generations with regard to skilled industrial professions, and potentially entice them to take up training in a relevant industry. Here’s why…

Over the last twenty years, phones entered the classroom. Teachers got annoyed and confiscated them and asked them to be put away. Now, teachers are asking students to get their phones out, as they now recognize that the operating systems and apps can allow them to do impressive things. The audio-visual combination has made phones a great way to consume information, but AR is allowing them to become interactive, engaging, and a real-time learning tool. Add to that engaging course materials, structure, objectives, and even gamification, and students are going to make greater progress with less effort. Technology has people’s social lives handheld (in a digital sense), so why not educational too?

Concluding Thoughts on AR for Industrial Training

Industrial bodies, organisations, and educational institutions are all working hard to narrow the skills gap through innovation and technology. The acknowledgement and development of augmented reality have proved incredible progressive for this journey, both as a way of maintaining existing skills and encouraging new talent to nurture. AR is low-hanging fruit, ripe for picking.

Image credit: Soldamatic / Stock Image Library

About the author

Sam is the Founder and Managing Editor of Auganix. With a background in research and report writing, he has been covering XR industry news for the past seven years.